The Ultimate Guide to Locomotive Diesel Engine Parts: Maximizing Efficiency and Reliability

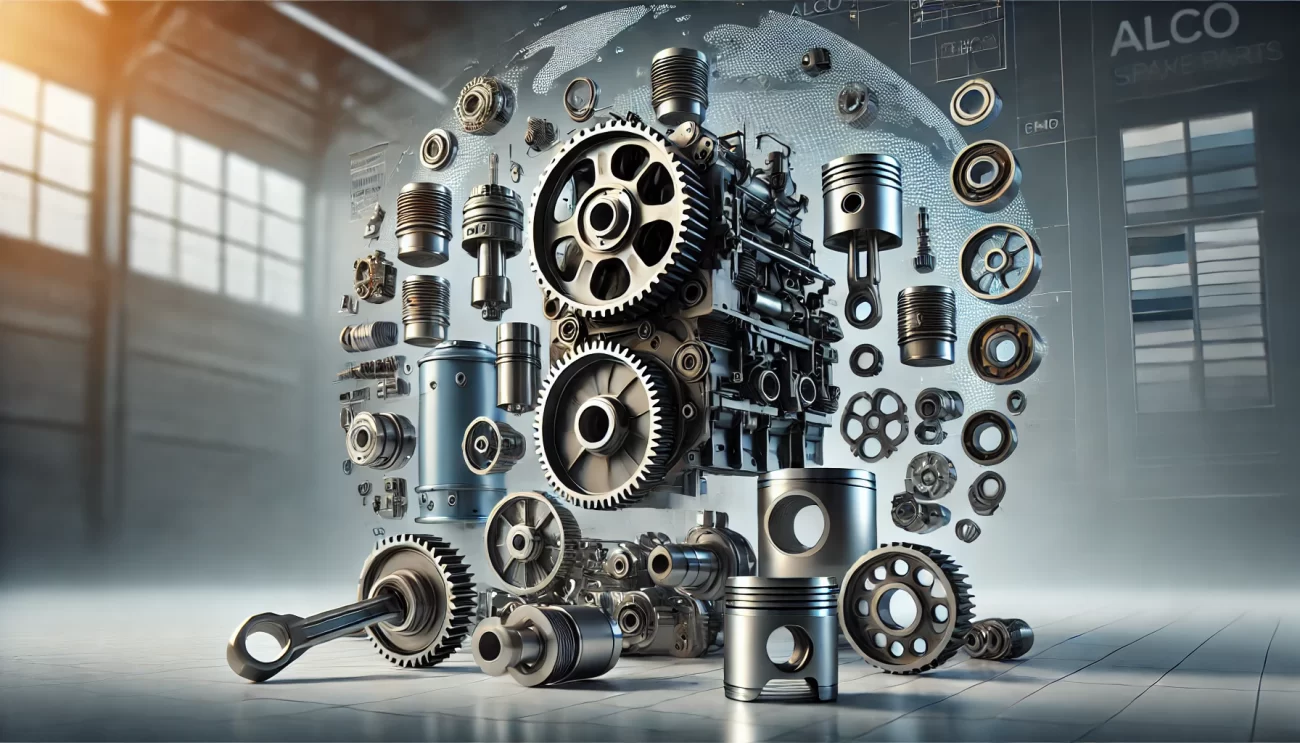

Railways have been the lifeblood of global transportation for nearly two centuries, powering economies and connecting distant regions. At the core of these steel giants lie diesel locomotive engines, complex marvels of engineering that transform fuel into motion. But what truly keeps these engines running efficiently for years, if not decades, are the precision-engineered components that make up their core.

This guide explores locomotive diesel engine parts in detail, revealing how each component contributes to reliability and performance. Whether you’re a rail operator, maintenance professional, or procurement manager, understanding these parts can mean the difference between seamless operations and costly downtime.

1. The Heart of Rail Transport: Why Diesel Engines Matter

While electric trains are gaining traction in some parts of the world, diesel locomotives remain the backbone of many national and industrial rail networks. Their self-contained power allows them to traverse remote areas without the need for overhead wires or third rails. But maintaining these heavy-duty engines is no small feat. Even a single faulty component can sideline an entire fleet, causing schedule disruptions and financial losses.

Unotech Engineering understands the stakes. As a leading provider of high-quality aftermarket locomotive parts, we prioritize durability, precision, and compatibility with major engine models like EMD, ALCO, and GE—ensuring minimal downtime and maximum operational success.

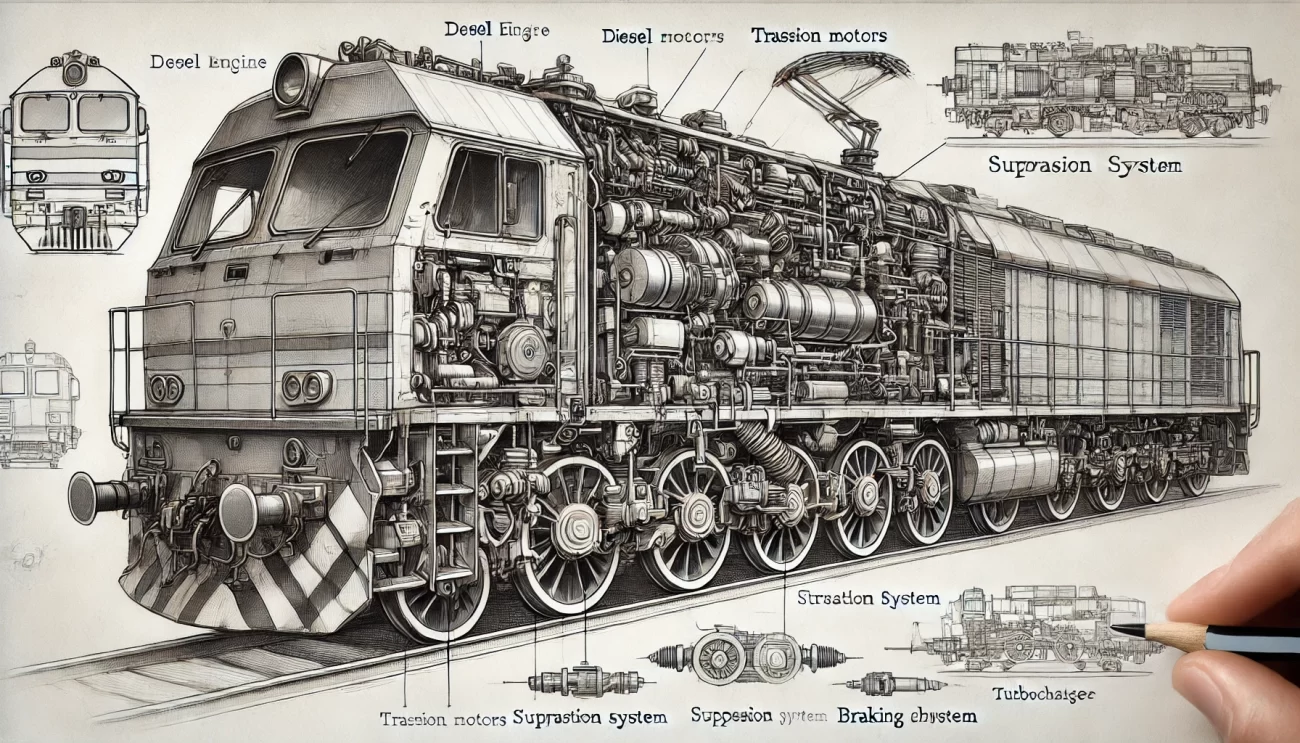

2. Key Components of a Diesel Locomotive Engine

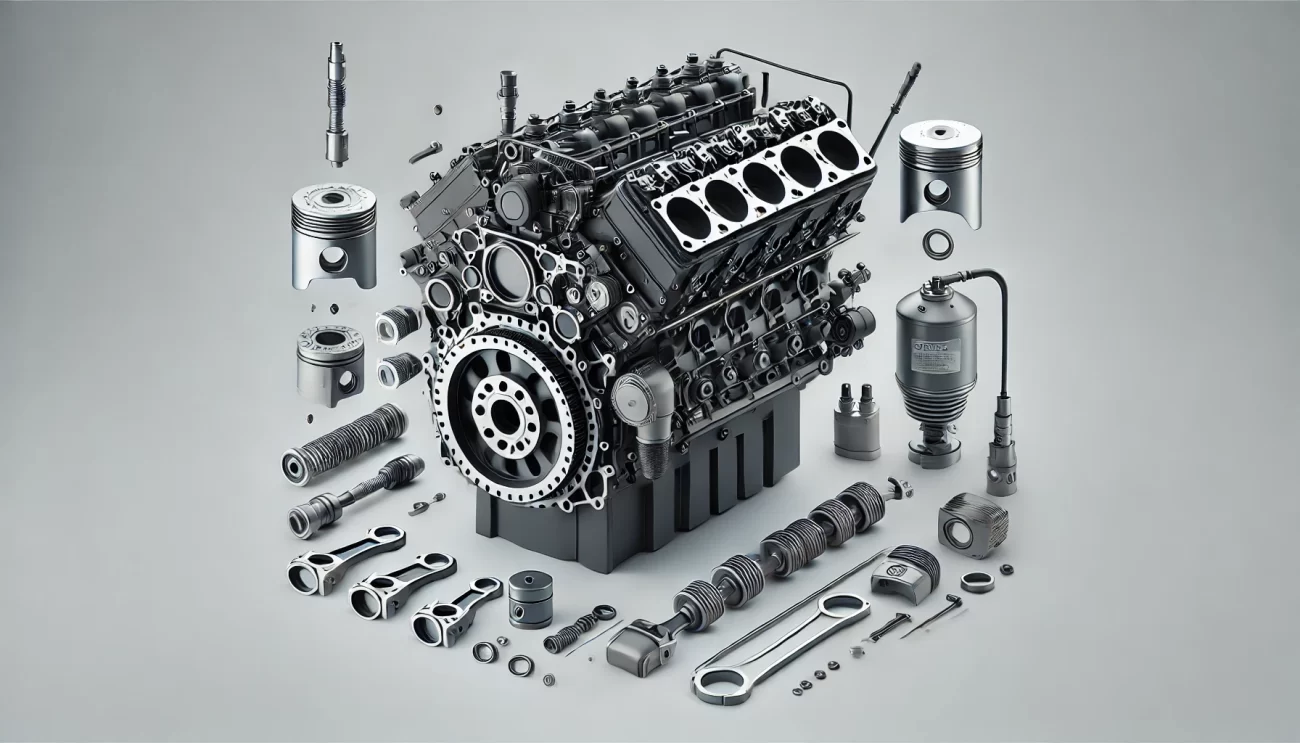

2.1 Cylinder Block & Cylinder Heads

- Cylinder Block: The engine’s foundation, housing multiple cylinders where fuel combustion occurs.

- Cylinder Heads: Seated atop the cylinder block, they contain valve passages, fuel injectors, and coolant channels.

- Importance: Precision-machined cylinder blocks and heads ensure proper compression, efficient fuel combustion, and reduced emissions.

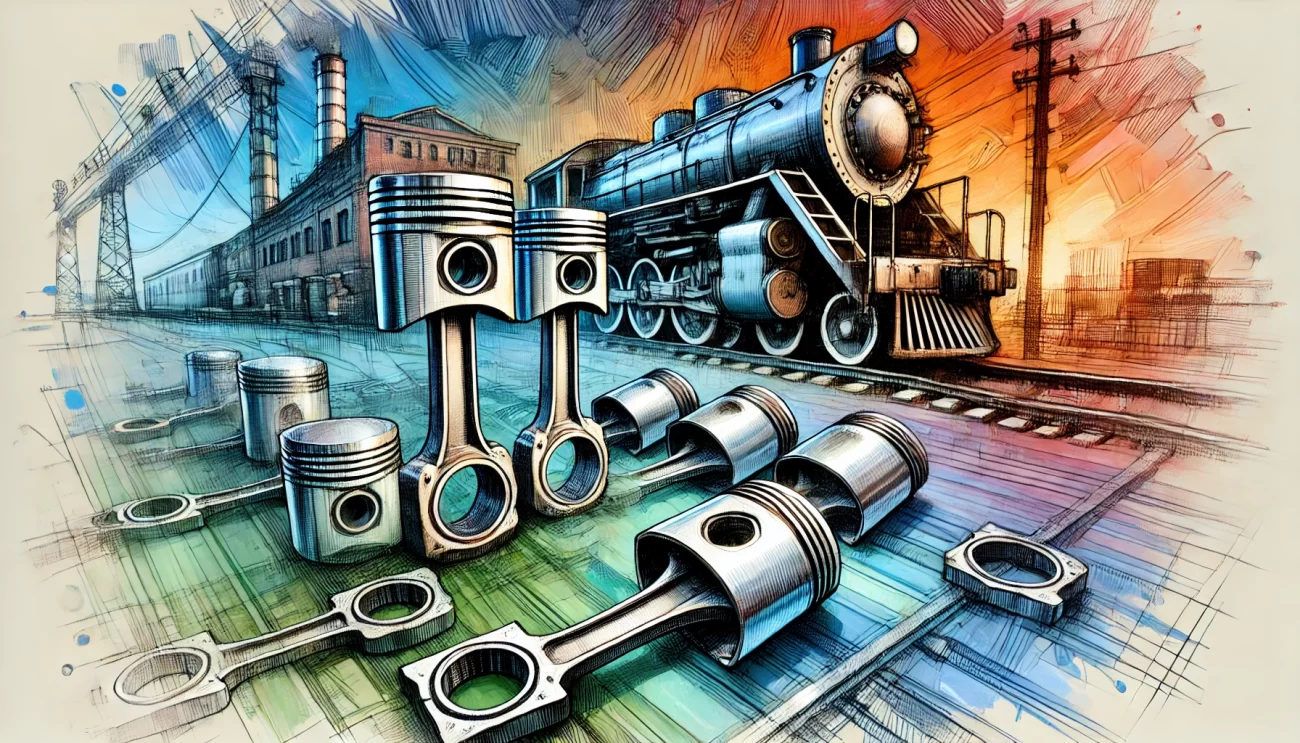

2.2 Pistons & Piston Rings

- Pistons: Convert the energy from fuel combustion into linear motion.

- Piston Rings: Seal the gap between the piston and cylinder wall, maintaining compression and preventing oil leakage.

- Benefits: High-grade pistons and rings increase engine efficiency and minimize wear, extending engine life.

2.3 Crankshaft & Connecting Rods

- Crankshaft: Transforms the pistons’ up-and-down motion into rotational force.

- Connecting Rods: Link the pistons to the crankshaft, transferring power to the locomotive’s drive system.

- Reliability Factor: Precision-engineered crankshafts and rods reduce vibrations, improving fuel economy and overall engine smoothness.

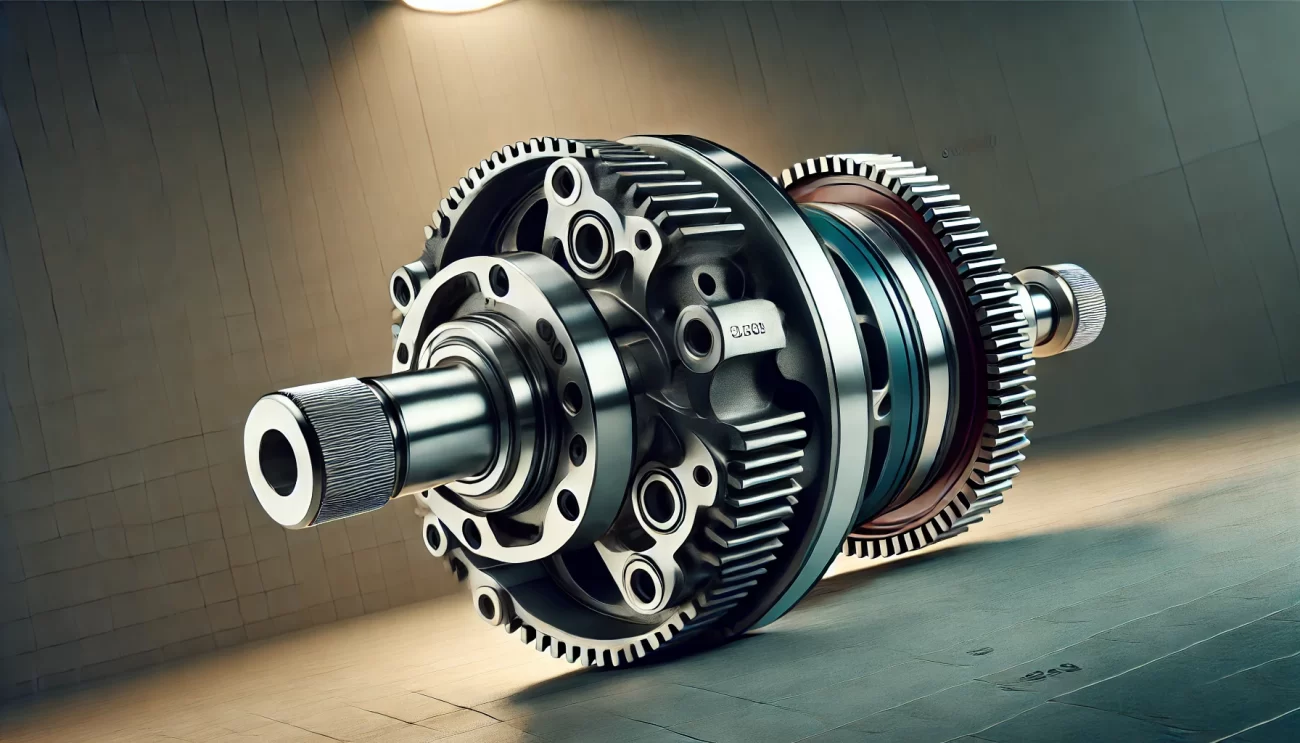

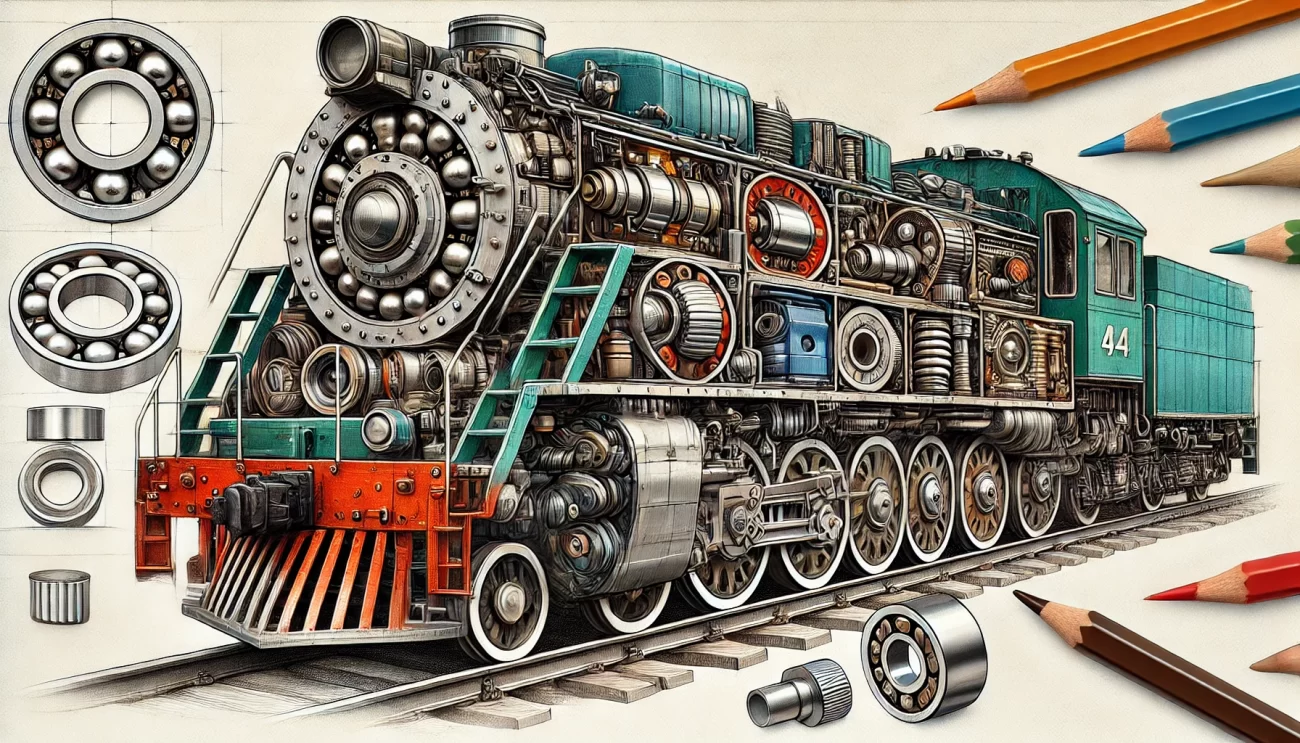

2.4 Bearings & Bushings

- Main Bearings: Support the crankshaft, minimizing friction under extreme loads.

- Bushings: Provide alignment and reduce wear in various engine components (e.g., rocker arms, camshafts).

- Unotech Advantage: Our OEM-quality bearings and bushings can handle high stress and extreme temperature variations, crucial for heavy-duty diesel engines.

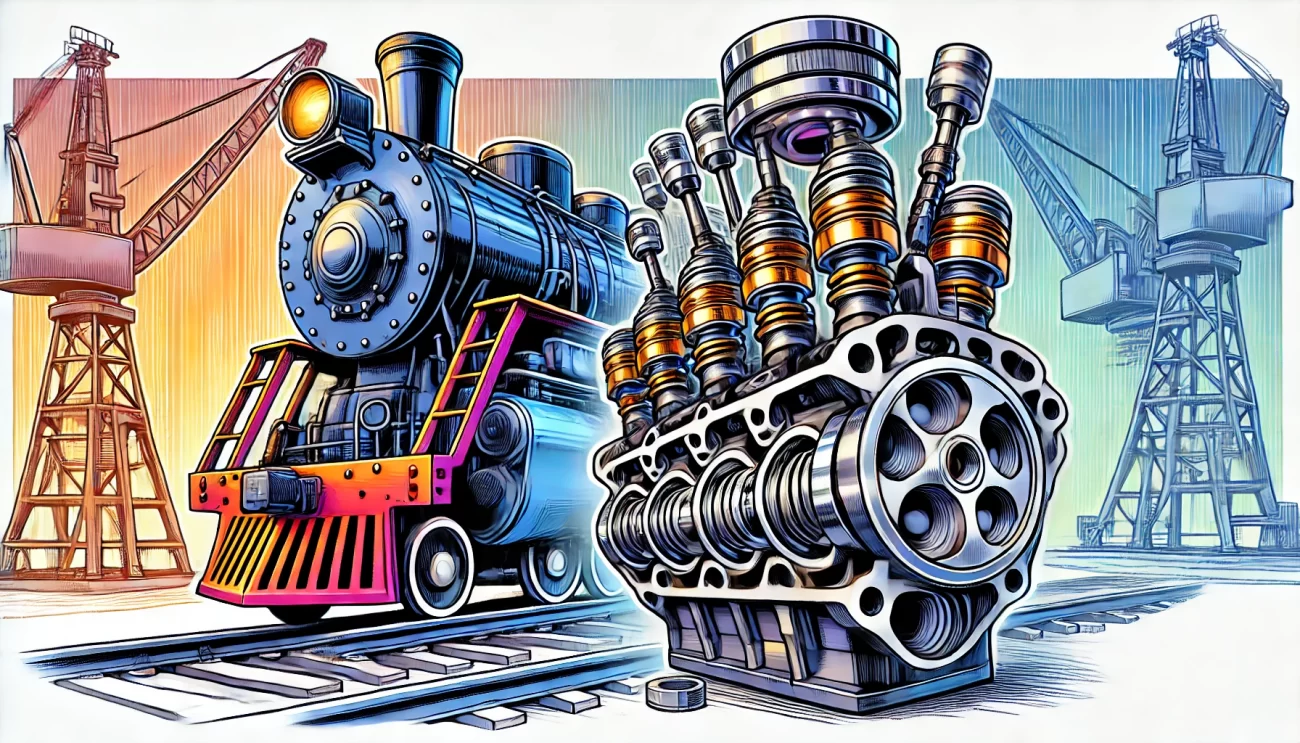

2.5 Fuel Injection System

- Injectors & Fuel Pumps: Deliver the right amount of diesel at high pressure into the combustion chamber.

- Significance: Proper injection timing and spray patterns are vital for maximizing power and minimizing emissions.

- Maintenance Tip: Even minor injector clogs can cause engine knock, reduced power, or higher fuel consumption.

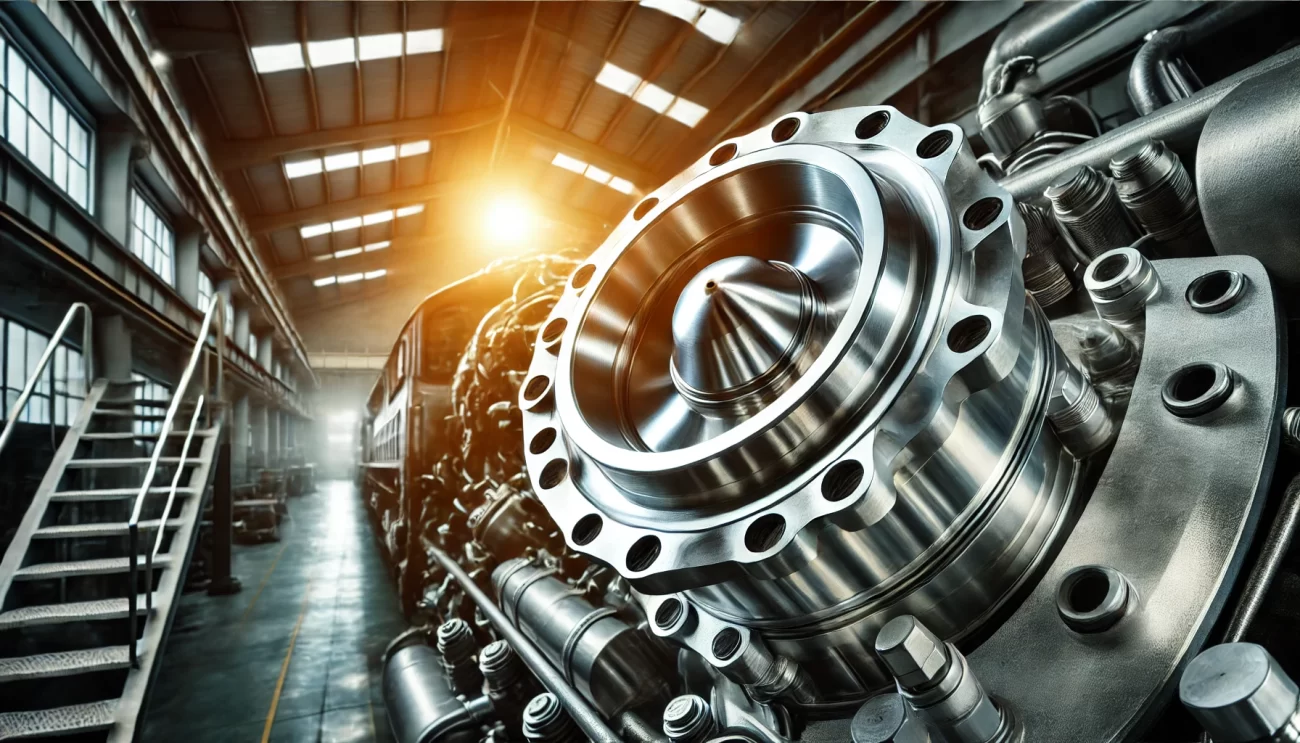

2.6 Turbochargers & Exhaust Systems

- Turbochargers: Force additional air into the combustion chamber, boosting engine power without increasing engine size.

- Exhaust Manifolds: Collect and channel exhaust gases away from the cylinders, maintaining efficient backpressure.

- Performance Boost: A well-maintained turbocharger can significantly increase horsepower and torque, essential for heavy freight or steep inclines.

2.7 Cooling & Lubrication Systems

- Radiators, Water Pumps, Thermostats: Keep engine temperatures in check, preventing overheating.

- Oil Pumps, Filters, & Passages: Supply lubricants to reduce friction and remove heat from moving parts.

- Key Insight: Proper cooling and lubrication are non-negotiable for diesel locomotives that run continuously over long distances.

3. Maintenance & Troubleshooting for Longevity

Even the most advanced diesel locomotive engine demands consistent care. Unotech Engineering recommends:

- Scheduled Oil Analysis

- Detect contaminants (e.g., metal shavings) that may indicate bearing or gear wear.

- Regular Filter Replacements

- Prevent debris from clogging injectors or damaging the cylinder walls.

- Predictive Maintenance

- Use sensors and IoT-based solutions to track component health, reducing unplanned downtime.

- Proper Storage of Spare Parts

- Keep components in climate-controlled conditions to avoid corrosion or degradation before use.

4. OEM vs. Aftermarket Locomotive Parts

Many operators assume that OEM parts are the only reliable choice. However, aftermarket components from a reputable supplier like Unotech Engineering can offer equivalent or superior performance at a more cost-effective rate. Our reverse engineering capabilities and strict quality controls ensure:

- Material Excellence: High-strength alloys and corrosion-resistant coatings.

- Exact Fit & Tolerances: Machined to match or exceed OEM specifications.

- Global Availability: Fast shipping and localized support in key markets.

5. Future Trends: The Next Generation of Diesel Engines

- Hybrid Diesel-Electric Systems: Some rail operators are experimenting with hybrid technologies to reduce emissions and fuel consumption.

- Advanced Coatings & Alloys: Nano-coatings on pistons and liners, along with high-grade steel alloys, can dramatically extend part life.

- AI & Machine Learning: Predictive analytics can optimize maintenance schedules, further reducing operating costs.

Despite the rise of alternative energy sources, diesel locomotives remain vital for long-haul freight, remote routes, and emergency backup. Keeping them at peak performance is an ongoing challenge that demands innovative engineering solutions.

6. Why Choose Unotech Engineering?

- Expertise Across Major Engine Models

- We supply parts for EMD, ALCO, and GE locomotives, among others.

- Uncompromising Quality

- Every component—from bearings and bushings to turbochargers—undergoes rigorous testing.

- Cost-Effective Solutions

- OEM-level performance without the premium price tag.

- Global Reach

- Serving railway operators across USA, Canada, South America, Europe, Africa, and beyond.

A Roadmap to Reliable Rail Operations

Locomotive diesel engines are the workhorses of modern rail networks, and their continued reliability depends on high-quality parts and proactive maintenance. From cylinder heads to turbochargers, each component plays a critical role in fuel efficiency, emission control, and mechanical longevity.

By partnering with Unotech Engineering, you gain access to top-tier locomotive diesel engine parts designed for maximum uptime and long-term cost savings. Whether you’re upgrading a fleet or solving a persistent maintenance challenge, our expertise ensures that your diesel locomotives remain on track—literally and figuratively.

Contact Unotech Engineering Today

Ready to upgrade your locomotive diesel engine parts for enhanced efficiency and reliability? Reach out to Unotech Engineering for expert guidance, top-tier components, and unparalleled support. Because when it comes to powering the future of rail, every part counts.