Precision Under Pressure: The Role of High-Performance Valves in Locomotive & Marine Engines

The Unsung Heroes of Engine Efficiency

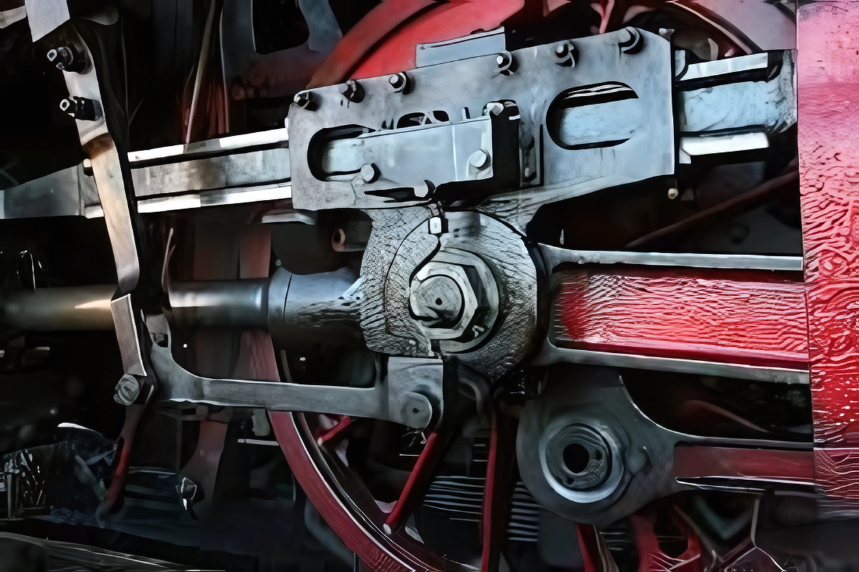

In the world of locomotive and marine engines, power, efficiency, and durability are critical to ensuring smooth operations across vast distances and challenging environments. While much attention is given to large components like pistons, crankshafts, and turbochargers, one of the most vital yet often overlooked elements of an engine is its valve system.

Valves control the lifeblood of an engine—air and fuel intake, and exhaust flow. A compromised valve can lead to decreased fuel efficiency, reduced power output, and even catastrophic engine failure. That’s why investing in high-quality locomotive and marine engine valves is essential for performance, longevity, and cost savings.

At Unotech Engineering, we specialize in precision-engineered engine valves that meet the rigorous demands of railway and marine applications, ensuring peak engine efficiency and reliability.

Why Engine Valves Are Critical for Locomotive & Marine Applications

Valves might seem like small components in an engine’s complex ecosystem, but they play a monumental role in overall performance. Here’s why they matter:

🚆 Power & Efficiency: Valves regulate the air and fuel mixture entering the combustion chamber, ensuring that the engine generates optimal power with minimal fuel consumption.

⚙️ Durability in Extreme Conditions: Locomotive and marine engines operate under extreme temperatures and high pressure. Valves must be able to withstand these conditions without warping, cracking, or losing efficiency.

⚓ Preventing Mechanical Failures: A faulty valve can cause backfiring, compression loss, and engine misfires, leading to costly repairs or complete engine overhauls.

💨 Emission Control & Compliance: Modern regulations require engines to minimize emissions. Well-designed valves ensure efficient fuel combustion, reducing environmental impact.

🔩 Enhanced Lifespan of Engine Components: Poor-quality valves accelerate wear and tear on pistons, cylinder heads, and exhaust systems. Investing in high-quality components helps extend engine life and reduce maintenance costs.

Unotech Engineering: Setting the Standard in Engine Valve Manufacturing

At Unotech Engineering, we pride ourselves on our cutting-edge manufacturing process, premium materials, and stringent quality control. Our locomotive and marine engine valves are built to enhance engine durability and efficiency in even the toughest operating conditions.

🔹 Specialized Expertise in Engine Valve Manufacturing

✔ Decades of experience in locomotive and marine engineering enable us to design valves optimized for high-performance engines.

✔ Our engineers understand the complexities of high-compression diesel engines, ensuring precision in every component.

🔹 Premium-Grade Materials for Maximum Durability

✔ Valves are manufactured using heat-resistant alloys, including stainless steel and high-strength titanium, for superior corrosion resistance and longevity.

✔ Our intake and exhaust valves are coated with special anti-wear treatments to withstand constant high-speed operations and thermal expansion.

🔹 Customization for Unique Engine Requirements

✔ No two engines are the same—our customization options ensure a perfect fit for diesel locomotives, marine propulsion systems, and power generation units.

✔ We tailor dimensions, coatings, and materials to match specific performance needs and operating environments.

🔹 Precision Engineering & Manufacturing

✔ Our state-of-the-art production facilities use CNC machining to achieve exceptional dimensional accuracy in every valve.

✔ We conduct comprehensive quality control, including pressure testing, thermal cycling, and endurance tests to ensure zero defects and optimal performance.

🔹 Wide Range of High-Performance Valves

✔ Intake Valves – Control the flow of air-fuel mixture into the combustion chamber for efficient power generation.

✔ Exhaust Valves – Allow the safe expulsion of combustion gases, ensuring reduced engine backpressure and better emissions control.

✔ Valve Seat Inserts – Protect the cylinder head by providing a hard-wearing, high-temperature-resistant surface for valve seating.

Did you know? A high-quality exhaust valve can withstand temperatures exceeding 1,400°F (760°C)—a testament to the engineering required for extreme durability.

Pro Tips: How to Choose the Right Engine Valves

Selecting the right locomotive or marine engine valves can be a game-changer in terms of engine efficiency and long-term maintenance costs. Here are key factors to consider:

1️⃣ Material & Heat Resistance

- Choose high-performance alloy valves that can withstand high combustion temperatures without deforming.

- Look for valves with special coatings that reduce friction and wear over time.

2️⃣ Precision & Fit

- Poorly manufactured valves can cause improper sealing, leading to compression loss.

- Always opt for precision-engineered components that meet OEM specifications.

3️⃣ Engine Compatibility

- Not all valves are the same—make sure your supplier provides valves specifically designed for your engine model.

- Unotech Engineering supplies valves for EMD, ALCO, WARTSILA, MAK, SULZER, and other major engine brands.

4️⃣ Maintenance & Longevity

- Choose valves that require minimal maintenance and can last for extended operational cycles without frequent replacements.

- Valves with self-cleaning properties or carbon-resistant coatings can significantly reduce buildup and engine fouling.

5️⃣ Work With a Reliable Supplier

- Avoid substandard or counterfeit parts that may cause engine failure.

- Partner with trusted manufacturers like Unotech Engineering for certified, high-quality valves.

Supporting Multiple Engine Platforms

Our OEM-quality locomotive and marine engine valves are compatible with leading engine brands, including:

✅ EMD Locomotive Engines

✅ ALCO Locomotive Engines

✅ MAK Marine Engines

✅ WARTSILA Marine Engines

✅ SULZER Marine Engines

✅ PIELSTICK Marine Engines

✅ B&W Marine Engines

By supplying top-tier components for these widely used engines, Unotech Engineering ensures seamless integration, extended service life, and improved fuel efficiency.

Why Choose Unotech Engineering?

✔ Precision Manufacturing & Rigorous Quality Control – Our valves undergo comprehensive testing to meet stringent industry standards.

✔ Reverse Engineering for Obsolete Parts – Need a valve no longer in production? We manufacture custom-engineered solutions for legacy engines.

✔ Trusted by Rail & Marine Industry Leaders – Our valves are used in locomotives, marine fleets, and industrial power systems worldwide.

✔ OEM & Aftermarket Solutions – Whether direct replacement or customized performance-enhanced options, we provide valves that meet your engine’s needs.

✔ Fast & Reliable Global Distribution – We ensure on-time delivery and dedicated technical support for clients across the globe.

Investing in Performance & Reliability

In the high-stakes world of locomotive and marine engineering, engine valves must be built to last. Investing in precision-engineered, high-performance valves ensures maximum fuel efficiency, durability, and long-term cost savings.

At Unotech Engineering, we provide industry-leading solutions that keep engines running stronger, longer, and more efficiently. Because when it comes to engine performance, reliability is everything.

📩 For bulk orders, technical specifications, or custom solutions, contact Unotech Engineering today.