How to Source Reliable Aftermarket Locomotive Parts Without Compromising on Quality

When it comes to locomotive maintenance, one truth is universal: the reliability of your fleet depends on the quality of its parts. In a global railway industry valued at over $200 billion, where efficiency and uptime are paramount, sourcing high-quality aftermarket locomotive parts is a make-or-break decision for procurement managers worldwide.

With Original Equipment Manufacturer (OEM) prices soaring and lead times stretching, aftermarket locomotive components have emerged as the go-to alternative. But how do you ensure that these parts meet the highest standards of durability and performance without breaking the bank? Here’s what you need to know.

The OEM vs. Aftermarket Debate: Why Aftermarket Wins

The assumption that OEM parts are always superior is rapidly changing. While OEM components are factory-tested, the aftermarket industry has evolved significantly—offering parts that match, and often exceed, OEM specifications. Companies like Unotech Engineering, a global leader in ALCO, EMD, and GE locomotive spare parts, provide precision-engineered solutions that are not just cost-effective but also backed by warranties.

Procurement managers are now prioritizing ISO-certified, OEM-quality parts that deliver the same reliability—without the OEM markup.

What to Look for When Sourcing Aftermarket Locomotive Parts

1️⃣ Manufacturing Standards & Certifications

- Ensure suppliers adhere to ISO 9001:2015 and IATF 16949 standards.

- Check if they supply parts to major railway OEMs or national rail networks.

2️⃣ Material & Engineering Precision

- High-quality engine bearings, pistons, bushings, and crankshafts should match OEM tolerances.

- Look for advanced metallurgy and CNC-machined components.

3️⃣ Supplier Track Record & Global Reach

- A trusted supplier should have a global presence—exporting to markets like the USA, Canada, EU, and Africa.

- Ensure they have experience developing parts for multiple locomotive models, such as EMD, ALCO, and GE/Wabtec engines.

4️⃣ Competitive Pricing Without Compromising Quality

- The best suppliers offer cost savings of 30-50% compared to OEMs while maintaining high performance.

- Always compare warranties and technical support before making a purchase.

Why Unotech Engineering is the Go-To Partner for Locomotive Spare Parts

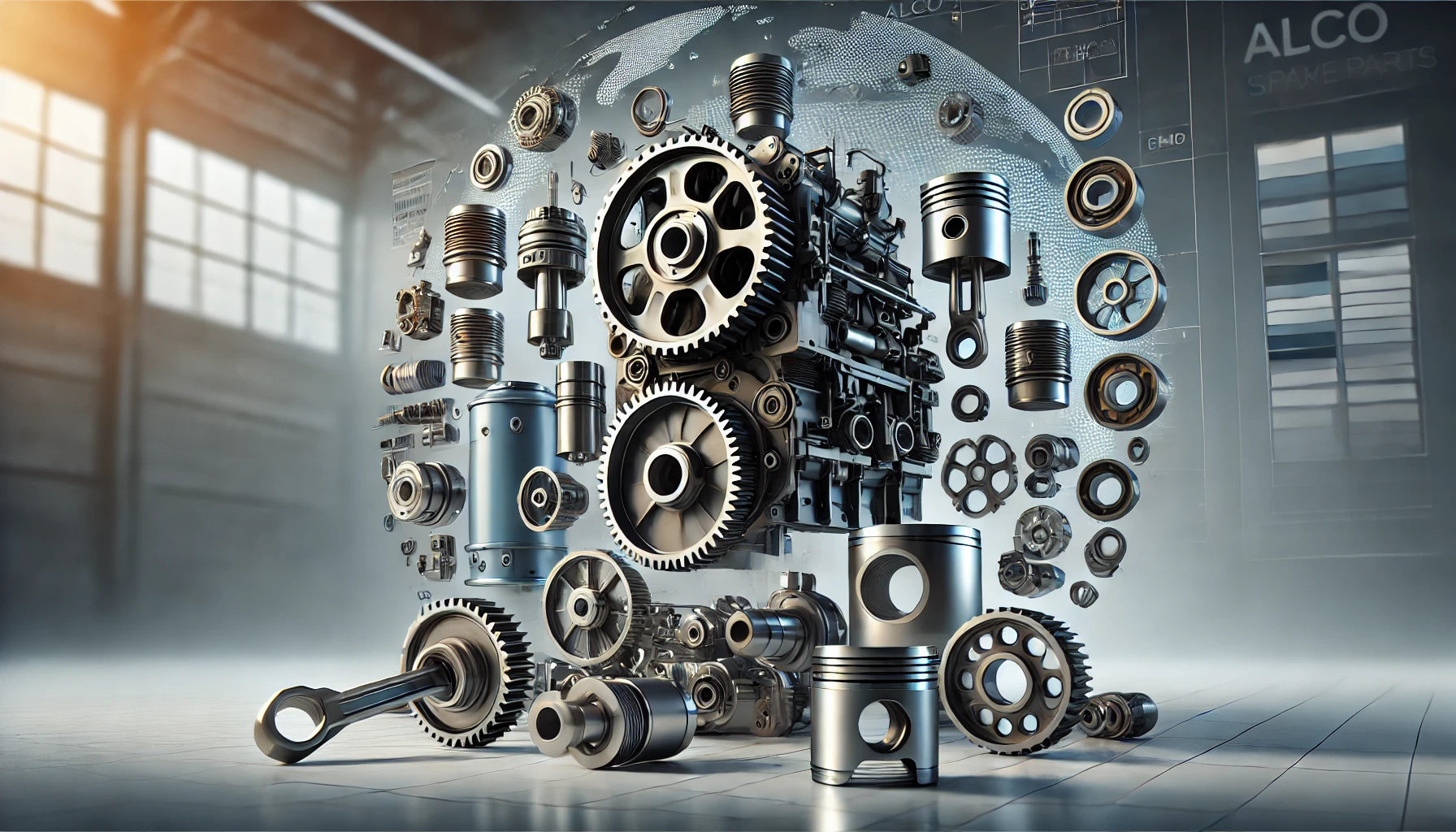

Unotech Engineering has redefined the aftermarket locomotive parts industry by ensuring that quality never takes a back seat to affordability. Specializing in EMD and ALCO locomotive spare parts, Unotech supplies:

✅ Crankshafts, Connecting Rods & Engine Bearings – Built to withstand extreme stress and long operational hours.

✅ Pistons, Piston Pins & Engine Valves – Precision-machined for seamless performance.

✅ Suspension Components & Bushings – Designed to enhance locomotive durability and smooth operation.

✅ Custom Parts Development – Unotech has the infrastructure to develop parts based on client designs or samples.

With its newly launched website, procurement managers can now easily browse components, request quotes, and access detailed specifications—making sourcing faster and more transparent than ever before.

Final Thought: The Future of Locomotive Parts Procurement

As railway operators worldwide face increased pressure to cut costs while maintaining operational efficiency, the demand for high-quality aftermarket locomotive spare parts will only rise. The key to success? Choosing suppliers that combine competitive pricing with uncompromising quality standards.

For procurement managers, the shift is clear: OEM-quality doesn’t have to come with an OEM price tag. The future of railway maintenance lies in reliable, precision-engineered aftermarket solutions.

Looking to source top-tier aftermarket locomotive parts? Explore Unotech Engineering’s full range today.