The Silent Workhorses: How Engine Bearings and Bushings Keep Locomotives Moving

In the roaring, steel-clad world of locomotives, we often celebrate the sheer power of diesel-electric engines and the rugged beauty of trains cutting across landscapes. But beneath that spectacle, hidden behind the hum of pistons and the thunder of wheels on rails, are two unsung heroes: engine bearings and bushings.

Without them, locomotives would grind to a catastrophic halt. Their role? Minimizing friction, preventing metal-on-metal destruction, and ensuring that thousands of tons of steel, freight, and human lives move seamlessly from one station to the next.

For decades, Unotech Engineering has been supplying precision-engineered engine bearings and bushings for the railway industry, ensuring that these critical components remain at peak performance.

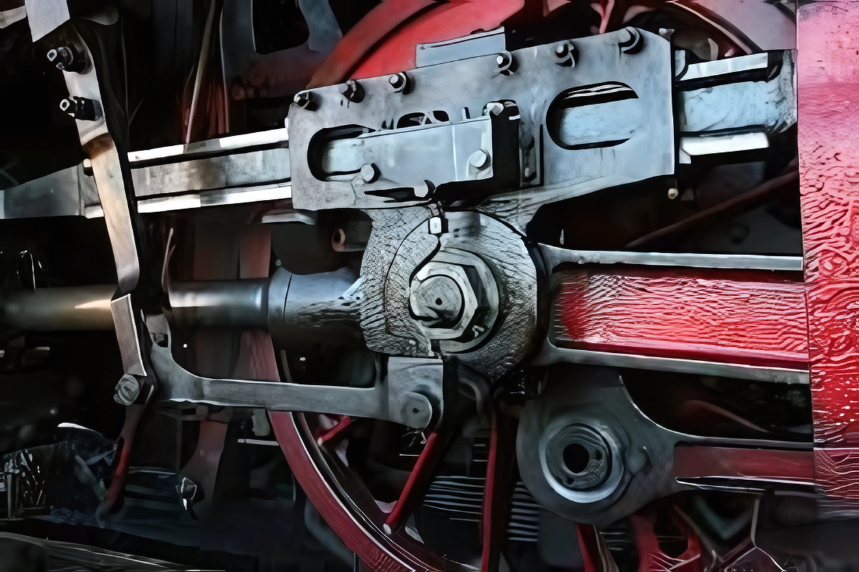

Engine Bearings: The Guardians of Power Transfer

If the locomotive’s crankshaft is the heart, then engine bearings are the arteries—responsible for keeping everything flowing without obstruction. Bearings ensure the rotating parts of an engine move smoothly, distributing immense loads while withstanding extreme heat and pressure.

How Engine Bearings Work

Inside a locomotive engine, the crankshaft converts linear piston movement into rotational force, transferring power to the wheels. Bearings act as a buffer, allowing this movement without excess friction or wear.

There are two main types of bearings used in locomotives:

- Main Bearings – Support the crankshaft, allowing it to rotate freely while handling enormous loads.

- Rod Bearings – Found in connecting rods, they ensure the pistons move without grinding against metal surfaces.

These components are made from durable materials such as tri-metal alloys, bronze, and babbitt metal, offering high wear resistance and self-lubrication properties.

Why They Matter: Without engine bearings, the crankshaft would seize, leading to catastrophic engine failure. Proper maintenance, lubrication, and sourcing high-quality bearings are critical to locomotive performance and longevity.

Unotech Engineering supplies precision-engineered engine bearings, designed for high durability and performance, ensuring locomotives operate efficiently even under extreme stress.

Bushings: The Silent Shock Absorbers

If engine bearings handle rotational movement, bushings deal with linear motion and vibration reduction.

Bushings, also known as plain bearings, are used in suspension systems, pivots, and joints throughout the locomotive to reduce vibration, noise, and metal wear.

Where Bushings Are Used in Locomotives

- Suspension Systems: Bushings absorb impact, ensuring a smoother ride and reducing stress on other locomotive components.

- Traction Motors & Axle Assemblies: They protect rotating parts from excessive wear, improving efficiency.

- Brake Systems: Used in linkages to ensure precise movement and wear reduction.

Unlike engine bearings, bushings are simpler in design but no less important. Made from bronze, steel-backed polymers, and self-lubricating composites, they can withstand high temperatures and extreme conditions.

Why They Matter: In a locomotive’s lifespan, bushings wear down due to stress and exposure. Failure to replace them leads to instability, increased vibrations, and eventual failure of critical components.

Unotech Engineering specializes in high-durability bushings designed to withstand high loads and extreme railway conditions, ensuring locomotives operate with maximum efficiency.

The Cost of Neglecting Bearings and Bushings

In 2019, a major railway operator in South America experienced a near-catastrophic engine failure due to bearing wear. Investigators found that improper lubrication and subpar replacement parts caused excess friction, leading to a seized crankshaft—resulting in a $1.2 million repair bill.

Similarly, in freight locomotives operating in the Middle East, the failure of suspension bushings led to uneven weight distribution, increasing maintenance costs by over 30% annually.

Both of these incidents underscore the importance of using high-quality bearings and bushings from trusted suppliers like Unotech Engineering.

How to Extend the Life of Bearings and Bushings in Locomotives

- Use High-Quality Materials – Always opt for OEM-grade or better components.

- Regular Lubrication – Prevents excess friction and overheating.

- Scheduled Inspections – Catch early signs of wear and prevent costly breakdowns.

- Proper Installation – Misalignment or incorrect installation reduces component lifespan.

- Reliable Sourcing – Partner with trusted suppliers like Unotech Engineering for precision-engineered locomotive components.

Conclusion: Small Components, Big Impact

For all their simplicity, engine bearings and bushings are indispensable to locomotive performance. They ensure smooth operation, minimize wear, and prevent costly failures, making them as vital as any major engine component.

With the global railway industry moving toward efficiency and sustainability, the demand for high-quality locomotive components has never been greater.

That’s where Unotech Engineering comes in—supplying high-precision bearings and bushings that keep locomotives running smoothly across the world.

Because when it comes to locomotives, even the smallest parts can make the biggest difference.