The Silent Force Behind Engine Efficiency: Bearings & Bushings in Railways and Marine Applications

The Critical Role of Bearings & Bushings in Heavy-Duty Machinery

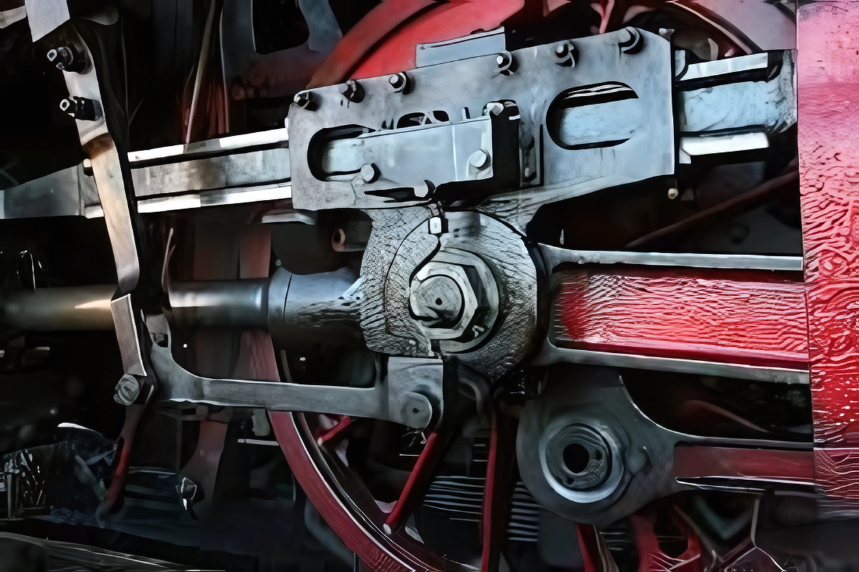

In the world of railways, marine vessels, and industrial machinery, certain components operate behind the scenes yet are indispensable to performance, durability, and safety. Among these, engine bearings and bushings play a vital role in reducing friction, supporting rotating components, and absorbing operational stress.

A high-performance diesel engine in a locomotive or marine vessel runs continuously, enduring high speeds, heavy loads, and extreme temperatures. Without properly engineered bearings and bushings, these machines would suffer from excessive wear, overheating, and mechanical failures—leading to costly downtime and repairs.

At Unotech Engineering, we specialize in precision-engineered bearings and bushings designed to meet the rigorous demands of locomotives, marine engines, and heavy industrial applications. Our solutions ensure enhanced performance, longer service life, and lower maintenance costs—keeping critical systems running smoothly.

How Bearings & Bushings Improve Engine Longevity

🚆 Reducing Friction & Wear: Bearings minimize contact between moving parts, allowing engines to function efficiently while preventing metal-to-metal damage.

⚙️ Supporting High Loads: Designed to withstand high-speed rotations and heavy mechanical loads, bushings absorb operational stress, protecting key components like camshafts, crankshafts, and connecting rods.

⚓ Dampening Vibrations & Noise: Excessive vibration in railway and marine engines can lead to premature wear, structural damage, and inefficient fuel consumption. Bearings and bushings help stabilize components, reducing vibrations and extending engine life.

🔩 Optimizing Efficiency: By ensuring smooth rotation and minimal friction, these components contribute to better fuel efficiency, reduced heat buildup, and lower emissions.

A faulty bearing or worn-out bushing can lead to unexpected failures, engine overheating, and even safety hazards. That’s why investing in high-quality replacements is essential.

Precision-Engineered Bearings & Bushings for Locomotive & Marine Applications

At Unotech Engineering, we offer a comprehensive range of bearings and bushings engineered for maximum durability and precision.

🔹 Main Engine Bearings – The Heart of Rotational Stability

- Designed to support crankshafts and reduce rotational friction.

- Manufactured from high-strength alloys to withstand extreme temperatures and pressures.

- Available for ALCO, EMD, MAK, WARTSILA, SULZER, PIELSTICK, and B&W engines.

🔹 Camshaft Bearings – Ensuring Precise Engine Timing

- Provide low-friction rotation for camshafts, which control engine valve operation.

- Crafted from wear-resistant materials to endure high-speed and high-pressure environments.

🔹 Rocker Arm Bushings – The Link Between Motion & Power

- Reduce wear in the valvetrain assembly, ensuring smooth valve operation.

- Engineered for tight tolerances, preventing power loss due to misalignment.

🔹 Thrust Washers – Controlling Axial Movement

- Prevent excessive crankshaft movement, maintaining optimal power transmission.

- Precision-machined for accurate fitting and long-term stability.

🔹 Connecting Rod Bearings – Handling the Power Transfer

- Absorb the force between pistons and crankshafts, ensuring smooth motion.

- Designed to resist wear under extreme load conditions.

🔹 Idler Gear Bearings – Reducing Gear Train Noise & Wear

- Support rotating gears in engine timing systems, ensuring accurate gear engagement.

- Prevent gear slippage and misalignment, reducing mechanical noise.

These precision-engineered components ensure reliable performance, smoother engine operation, and long-term cost savings in both railway and marine engines.

Selecting the Right Bearings & Bushings: What to Look For

Choosing the right bearings and bushings can have a significant impact on engine longevity, maintenance costs, and overall operational efficiency. Here are key factors to consider:

1️⃣ Material Quality & Coating

- Select components made from heat-resistant, high-strength alloys to withstand continuous wear and friction.

- Unotech Engineering bearings use corrosion-resistant coatings to improve durability, especially in marine environments where exposure to moisture and salt can accelerate degradation.

2️⃣ Compatibility with Engine Models

- Not all bearings and bushings are interchangeable—precision matters.

- Our products are designed for direct compatibility with ALCO, EMD, WARTSILA, and other major engine types to ensure seamless integration and easy installation.

3️⃣ Load-Bearing Capacity

- Bearings and bushings should match the load specifications of the engine to prevent premature wear or failure.

- Our main bearings and crankshaft bushings are designed for high-load endurance, making them ideal for heavy-duty railway and marine applications.

4️⃣ Lubrication Efficiency

- Proper lubrication reduces heat buildup and wear, extending the life of the components.

- Our self-lubricating bushings reduce the need for frequent maintenance while improving performance.

5️⃣ Supplier Reliability & Technical Support

- Work with trusted suppliers who provide certified, precision-engineered products and technical expertise.

- Unotech Engineering provides global distribution, rapid order fulfillment, and expert support to help customers choose the right bearings and bushings for their applications.

Supporting Multiple Engine Platforms

We supply OEM-quality bearings and bushings for leading railway and marine engine brands, including:

✅ ALCO Locomotive Engines

✅ EMD Locomotive Engines

✅ MAK Marine Engines

✅ WARTSILA Marine Engines

✅ SULZER Marine Engines

✅ PIELSTICK Marine Engines

✅ B&W Marine Engines

With Unotech Engineering’s industry-leading products, customers can ensure smooth, efficient, and long-lasting engine performance.

Why Unotech Engineering?

✔ Precision Engineering & Rigorous Quality Control – Every component undergoes strict quality inspections to meet global industry standards.

✔ Reverse Engineering for Obsolete Components – We manufacture discontinued or hard-to-source parts, ensuring that older engines remain operational.

✔ Trusted by Rail & Marine Industry Leaders – Our components are used by locomotive fleets and marine operators worldwide.

✔ OEM & Aftermarket Solutions – We offer both direct replacement parts and custom-engineered solutions to meet specific application needs.

✔ Fast & Reliable Global Distribution – We ensure on-time delivery and dedicated customer support for orders worldwide.

Final Thoughts: Investing in Durability & Performance

In the high-demand world of railway and marine engineering, engine bearings and bushings are mission-critical components. They directly impact fuel efficiency, engine lifespan, and maintenance costs—making the quality of these components non-negotiable.

At Unotech Engineering, we deliver industry-leading solutions to ensure superior durability, precision performance, and long-term reliability. Whether for locomotives, marine engines, or industrial applications, our OEM-quality bearings and bushings help keep engines running at peak efficiency.

Because in industries where failure is not an option, reliability is everything.

📩 For bulk orders, technical specifications, or custom engineering solutions, contact Unotech Engineering today.