The Role of Precision Engineering in the Defence Industry: How High-Quality Components Enhance Military Vehicles and Equipment

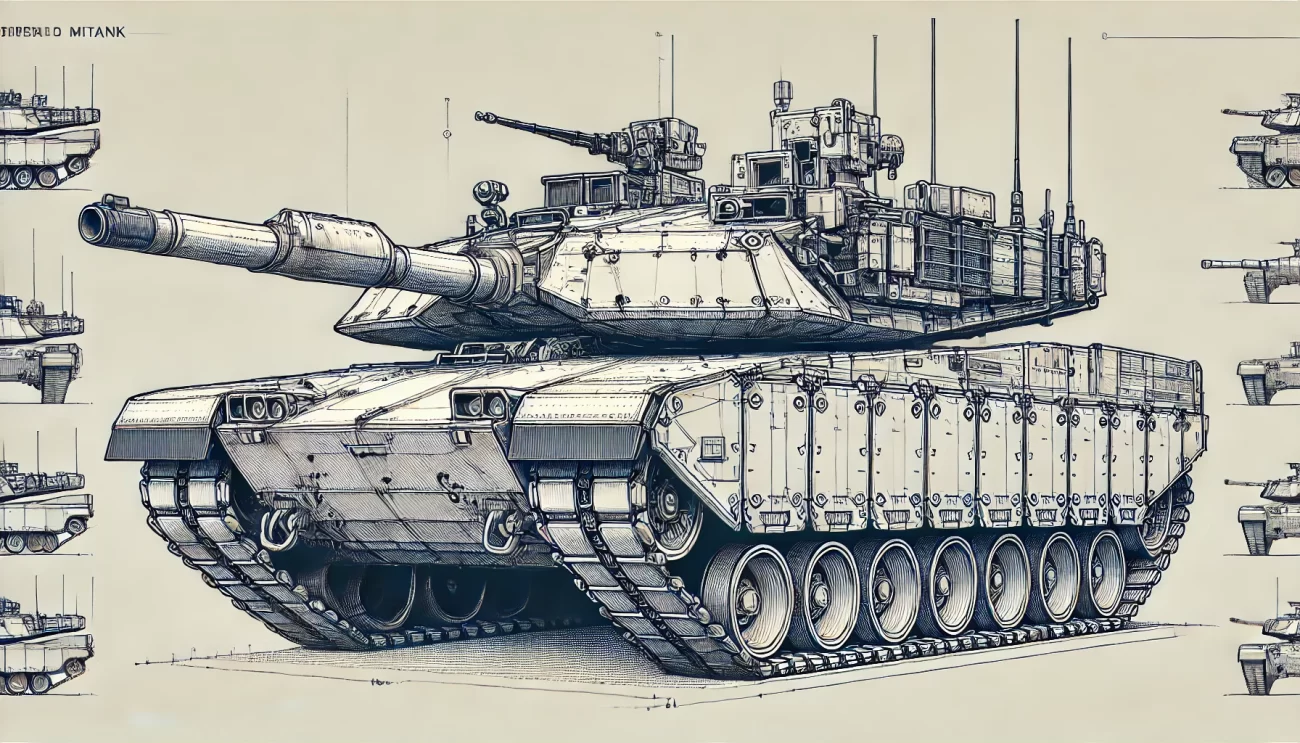

When a T-90 tank rolls onto the battlefield or a military transport truck speeds through rough terrain, the margin for error is zero. Every component—from engine bearings to suspension bushings—must perform flawlessly under extreme stress, heat, and environmental conditions.

In the defence industry, the difference between success and failure, mobility and breakdown, victory and defeat often comes down to the quality of its engineering. Military vehicles and equipment demand high-performance, precision-engineered components that can withstand heavy loads, high temperatures, and prolonged operation without failure.

For years, Unotech Engineering has been a trusted supplier of critical defence components, providing OEM-grade engine bearings, bushings, suspension parts, and crankshaft components for T-72 and T-90 tanks, armored vehicles, and defence transport fleets.

But why is precision engineering so critical in modern defence applications? And how do these small components ensure maximum reliability on the battlefield?

Precision Engineering in Military Vehicles: Why Every Part Matters

In civilian vehicles, engine failure or suspension wear means inconvenience. In a military setting, it could mean mission failure—or worse, lives lost.

Military tanks, armored carriers, and transport vehicles are designed to operate in harsh, unpredictable environments—deserts, frozen tundras, dense forests, and combat zones where immediate repairs are not an option.

🚛 Challenges Faced by Military Vehicles:

- High temperatures in combat zones strain engines and moving parts.

- Heavy loads require reinforced components to handle extreme stress.

- Continuous use with little downtime increases wear and tear.

- Unforgiving terrain demands superior suspension and shock absorption.

How Precision-Engineered Components Make a Difference

Each component of a military vehicle is designed for maximum efficiency, durability, and longevity. Unotech Engineering provides high-performance parts that are battle-tested and field-proven.

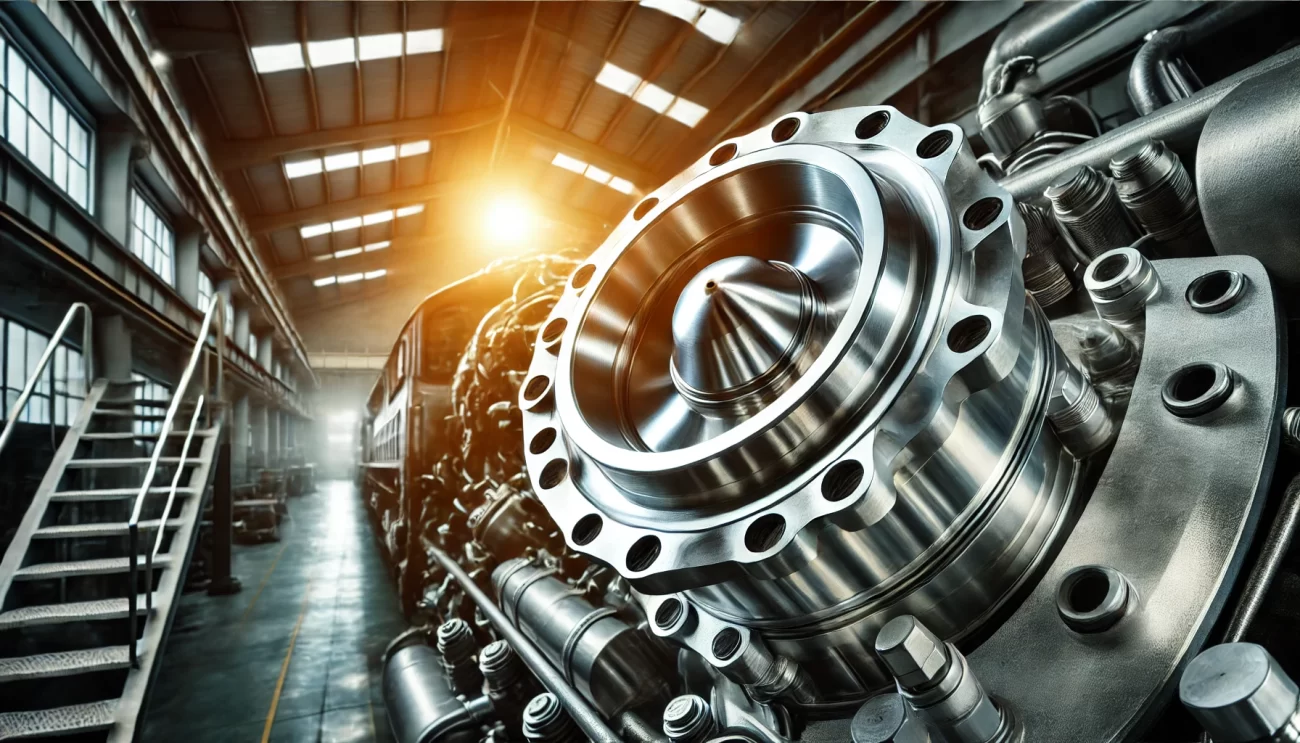

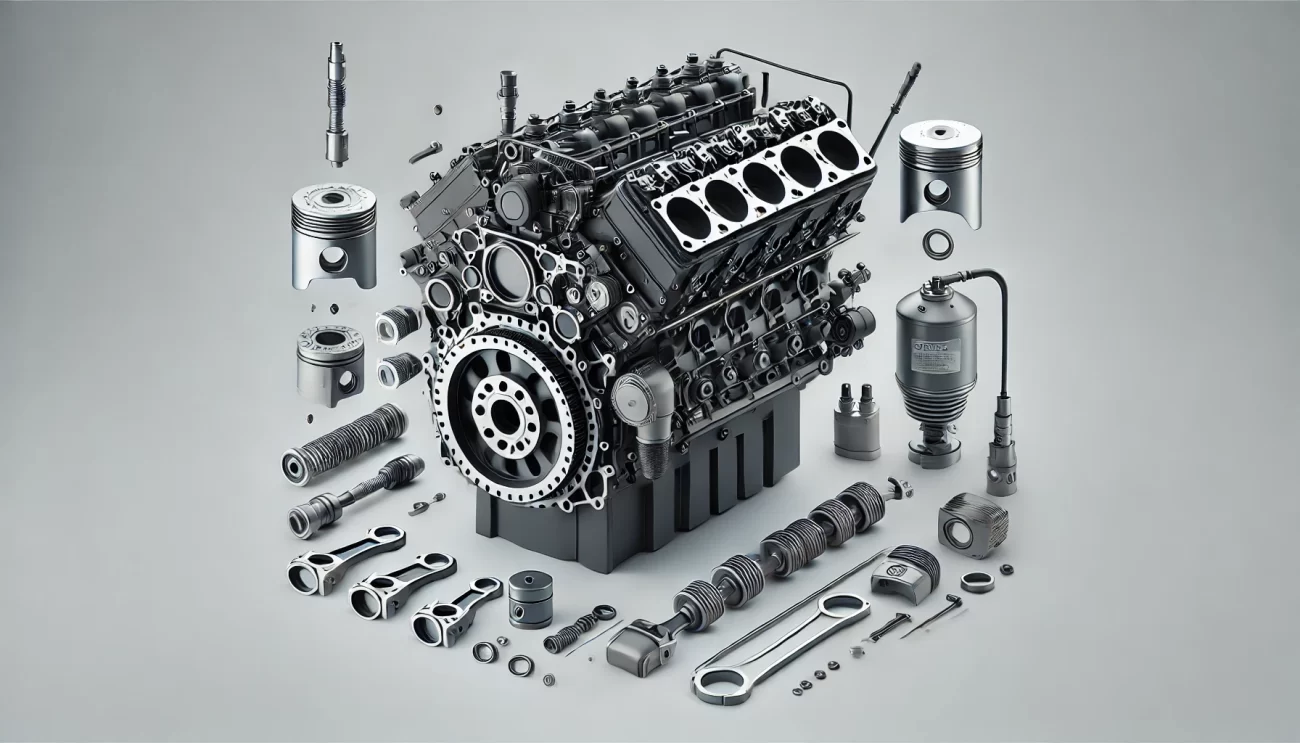

🔧 Engine Bearings: Reduce friction and heat buildup in high-power diesel engines, extending operational life.

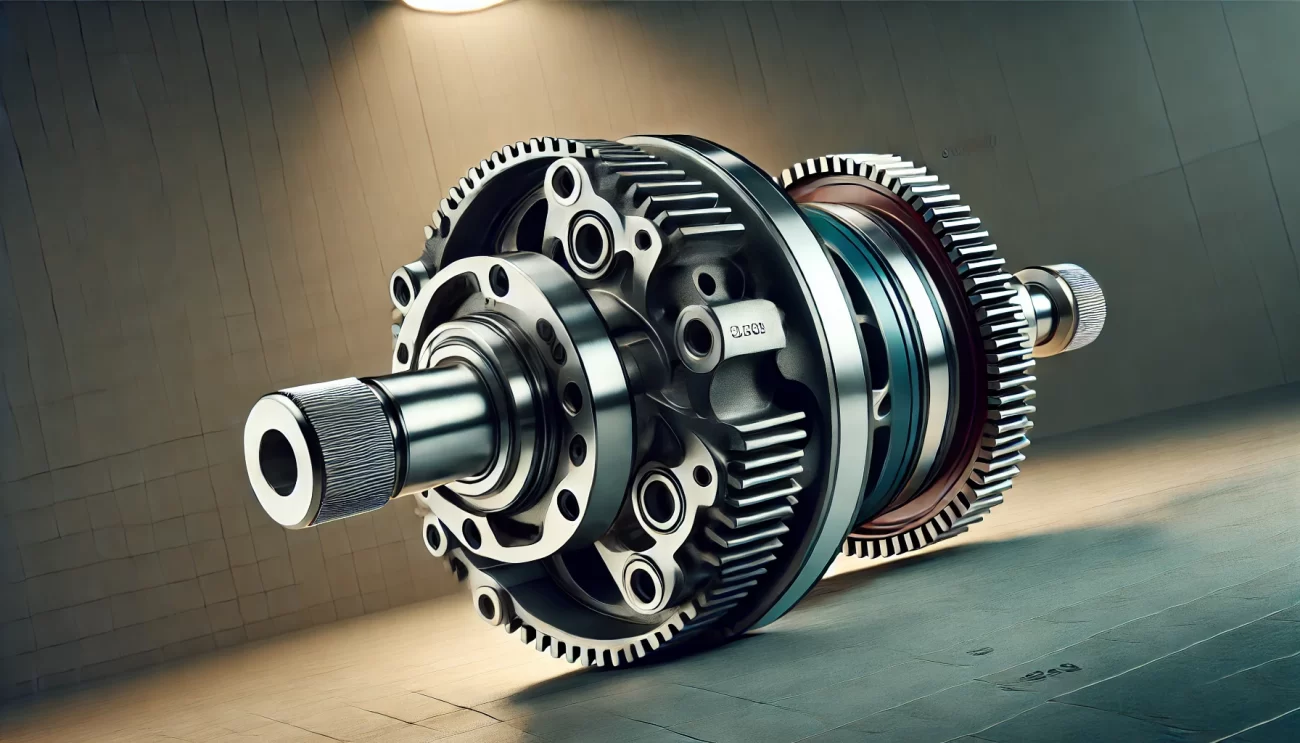

🔧 Bushings: Absorb impact and reduce vibration, ensuring smooth vehicle operation across rough terrain.

🔧 Suspension Parts: Strengthen vehicle stability, preventing excessive wear on axles and tracks.

🔧 Crankshaft Components: Ensure seamless power transfer, maximizing fuel efficiency and engine lifespan.

Without these critical components, a military vehicle is nothing more than a metal shell—prone to failure when it’s needed the most.

Unotech Engineering supplies OEM-quality defence components, ensuring that T-72 and T-90 tanks, military trucks, and armored personnel carriers remain mission-ready at all times.

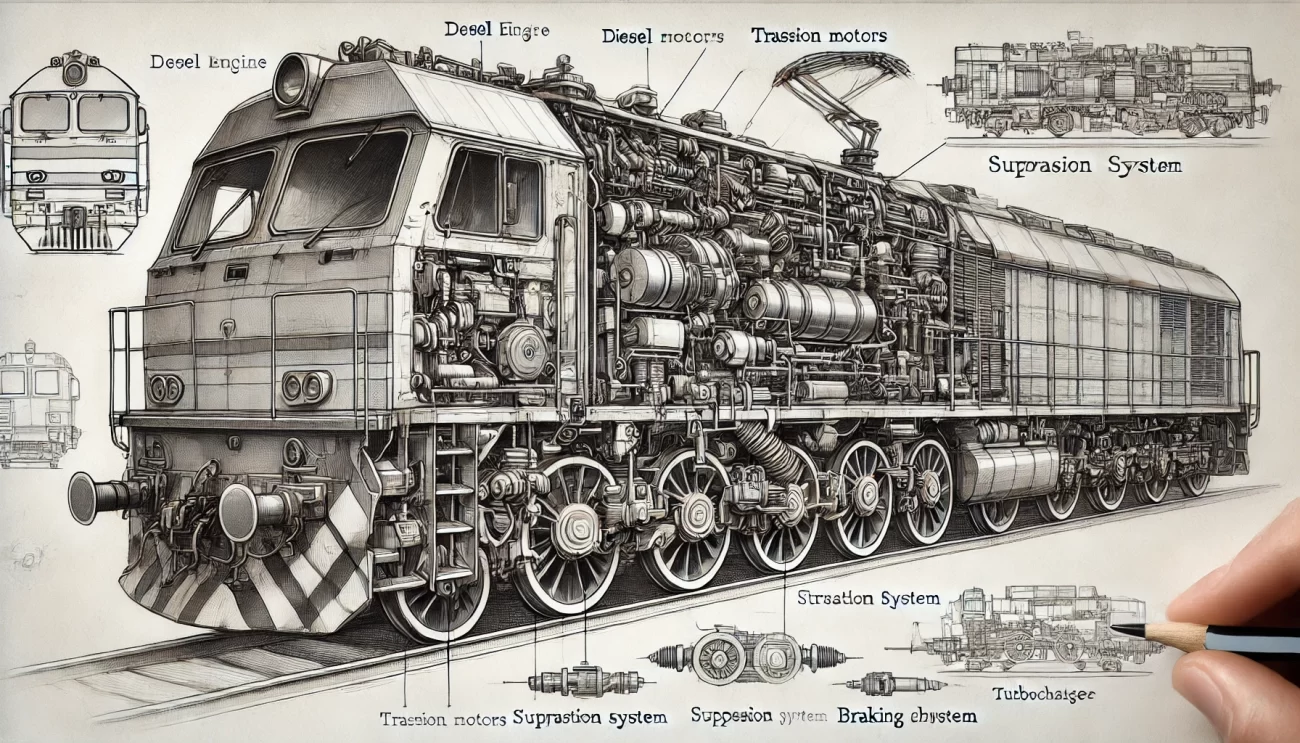

The Evolution of Military Engine Technology: Stronger, Faster, More Reliable

In modern warfare, military vehicles are expected to perform longer missions with fewer breakdowns. As technology advances, defence manufacturers are pushing for greater fuel efficiency, extended engine life, and smarter diagnostics to detect early failures.

⚙️ Key Advancements in Military Vehicle Engineering:

✅ Improved Heat Resistance: Military-grade engine bearings now use high-durability alloys that withstand extreme temperatures.

✅ Better Fuel Efficiency: New crankshaft designs maximize power transfer, reducing energy loss.

✅ Smart Sensors & Predictive Maintenance: AI-powered systems monitor component health, reducing unexpected breakdowns.

✅ Reinforced Suspension Systems: Advanced bushings and dampers minimize vibration for smoother movement over rough terrain.

Military forces worldwide invest billions in upgrading their vehicle fleets—but even the most advanced tank is only as reliable as its smallest components.

Unotech Engineering ensures that defence organizations receive the highest-quality parts, keeping military vehicles running with maximum efficiency and durability.

Why Substandard Parts Are a Major Risk in Defence Applications

The stakes in defence engineering are too high for low-quality, unreliable spare parts. A single faulty engine bearing or substandard bushing could compromise an entire mission.

📌 Consequences of Using Poor-Quality Spare Parts in Military Vehicles:

🚨 Increased Failure Rates: Inferior components wear out quickly, leading to breakdowns in the field.

🚨 Higher Maintenance Costs: Frequent replacements result in increased downtime and operational expenses.

🚨 Mission Risk: A stalled tank in a combat zone is a liability, not an asset.

🚨 Reduced Vehicle Lifespan: Low-quality parts accelerate degradation, forcing early decommissioning of expensive assets.

This is why military procurement teams and defence contractors partner with trusted suppliers like Unotech Engineering to ensure that every part meets the highest durability and safety standards.

The Future of Military Engineering: Next-Generation Defence Components

As global conflicts and defence strategies evolve, military engineering must keep pace with changing battlefield demands. Next-generation military vehicles will require lighter, stronger, and more efficient components.

🔬 Upcoming Innovations in Defence Engineering:

✅ 3D-Printed Engine Parts: Precision-manufactured components for faster repairs.

✅ Lightweight Composite Materials: Stronger yet lighter metals for improved fuel efficiency.

✅ AI-Based Predictive Diagnostics: Reducing failures by detecting weaknesses before breakdowns occur.

✅ Electrification & Hybrid Powertrains: The push for lower emissions and improved range.

The next decade will see a major shift toward automation, data-driven maintenance, and fuel-efficient defence vehicles—but even with new technologies, the need for precision-engineered components remains constant.

Unotech Engineering is committed to supporting the future of military mobility, supplying state-of-the-art defence components for modern military fleets worldwide.

Strength in Every Detail

Military vehicles are built to endure, but their performance relies on the strength and precision of every individual component. From engine bearings and bushings to crankshaft parts and suspension components, every part plays a role in keeping defence fleets operational.

By investing in high-quality spare parts and predictive maintenance, military forces reduce downtime, minimize costs, and maximize mission success.

That’s why Unotech Engineering remains a trusted partner in the defence industry, delivering the precision, durability, and reliability needed for mission-critical operations.

Because in defence, every second counts—and every component matters.