How to Extend the Lifespan of Locomotive Spare Parts: Best Practices for Maintenance and Performance

In the world of rail transport, where efficiency, reliability, and longevity dictate success, locomotives must be maintained with precision. Every spare part—from engine bearings and bushings to pistons and suspension components—plays a critical role in ensuring smooth operation.

Yet, locomotives endure intense mechanical stress, extreme weather conditions, and heavy loads, making wear and tear inevitable. The key to minimizing breakdowns and maximizing efficiency isn’t just about replacing parts when they fail—it’s about proactive maintenance and using high-quality components from trusted suppliers like Unotech Engineering.

So, how can railway operators extend the lifespan of locomotive spare parts and reduce costly repairs? Let’s explore the best practices for locomotive maintenance and performance optimization.

1. Prioritize Preventive Maintenance Over Reactive Repairs

Many railway companies operate under a “run-to-failure” mentality, replacing parts only when they break. This approach, however, increases downtime, raises operational costs, and can even lead to catastrophic failures.

Instead, a preventive maintenance strategy ensures that spare parts are replaced before failure occurs, preventing disruptions and enhancing locomotive efficiency.

🔹 Recommended Practice: Implement a condition-based monitoring system (CBM) that tracks real-time performance data of critical components like crankshafts, bearings, and brake systems. Advanced sensors can detect early signs of wear, vibration anomalies, and temperature spikes, signaling when maintenance is required.

Unotech Engineering provides high-performance spare parts designed for longer wear cycles and minimal degradation, ensuring that preventive maintenance efforts yield maximum reliability and cost savings.

2. Use High-Quality Spare Parts from Trusted Suppliers

Not all locomotive spare parts are created equal. Cheap, low-quality replacements may seem like a cost-saving solution initially, but they wear out faster, require more frequent replacements, and can cause further damage to the locomotive.

For example, engine bearings made from inferior materials degrade quickly, leading to excessive crankshaft friction and overheating. Similarly, poor-quality bushings deteriorate under load, reducing suspension stability and causing premature failure.

🔹 Recommended Practice: Always source spare parts from reliable manufacturers like Unotech Engineering, which provides OEM-grade and precision-engineered locomotive components that meet industry standards for durability and performance.

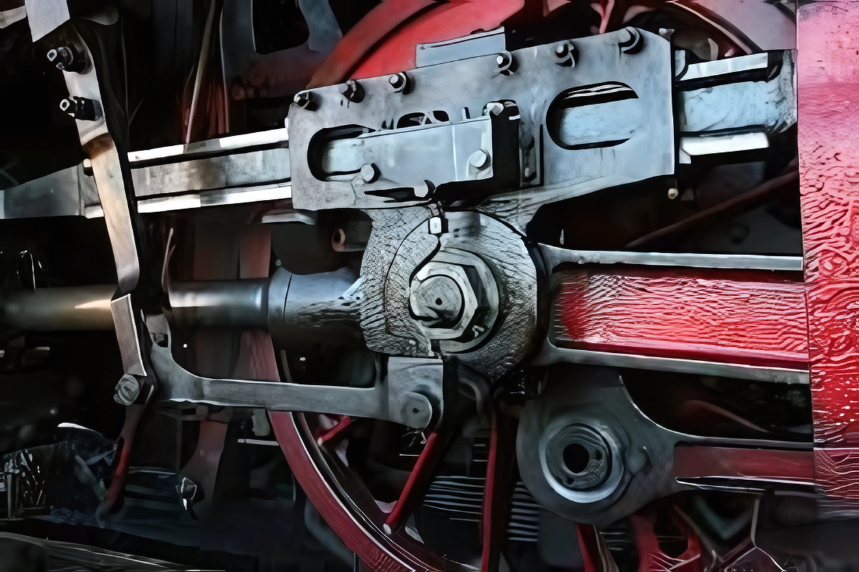

3. Lubrication: The Lifeline of Locomotive Components

Friction is the enemy of engine bearings, pistons, crankshafts, and suspension systems. Without proper lubrication, metal-on-metal contact accelerates wear and leads to overheating, performance loss, and even engine seizures.

However, lubrication is more than just applying oil or grease—it’s about choosing the right lubricants and applying them correctly.

🔹 Recommended Practice:

✅ Use high-viscosity, railway-grade lubricants designed for high-load applications.

✅ Follow manufacturer-recommended lubrication schedules to prevent excessive build-up or dry operation.

✅ Monitor for contaminants—dust, moisture, and fuel leaks can degrade lubricants, reducing their effectiveness.

Unotech Engineering’s spare parts are designed for superior lubrication efficiency, ensuring smoother operation and lower maintenance requirements.

4. Store Spare Parts in a Controlled Environment

Storage conditions directly impact the lifespan of locomotive spare parts. Humidity, extreme temperatures, and improper stacking can lead to corrosion, material degradation, and deformation, especially for components like engine bearings, bushings, and rubber-based parts.

🔹 Recommended Practice:

✅ Store parts in a clean, dry, and temperature-controlled environment.

✅ Keep engine components in sealed, oil-coated packaging to prevent corrosion.

✅ Use FIFO (First-In, First-Out) inventory management to ensure older stock is used before newer stock.

Unotech Engineering ensures that all spare parts are delivered in high-quality, protective packaging to maintain their integrity during storage and transport.

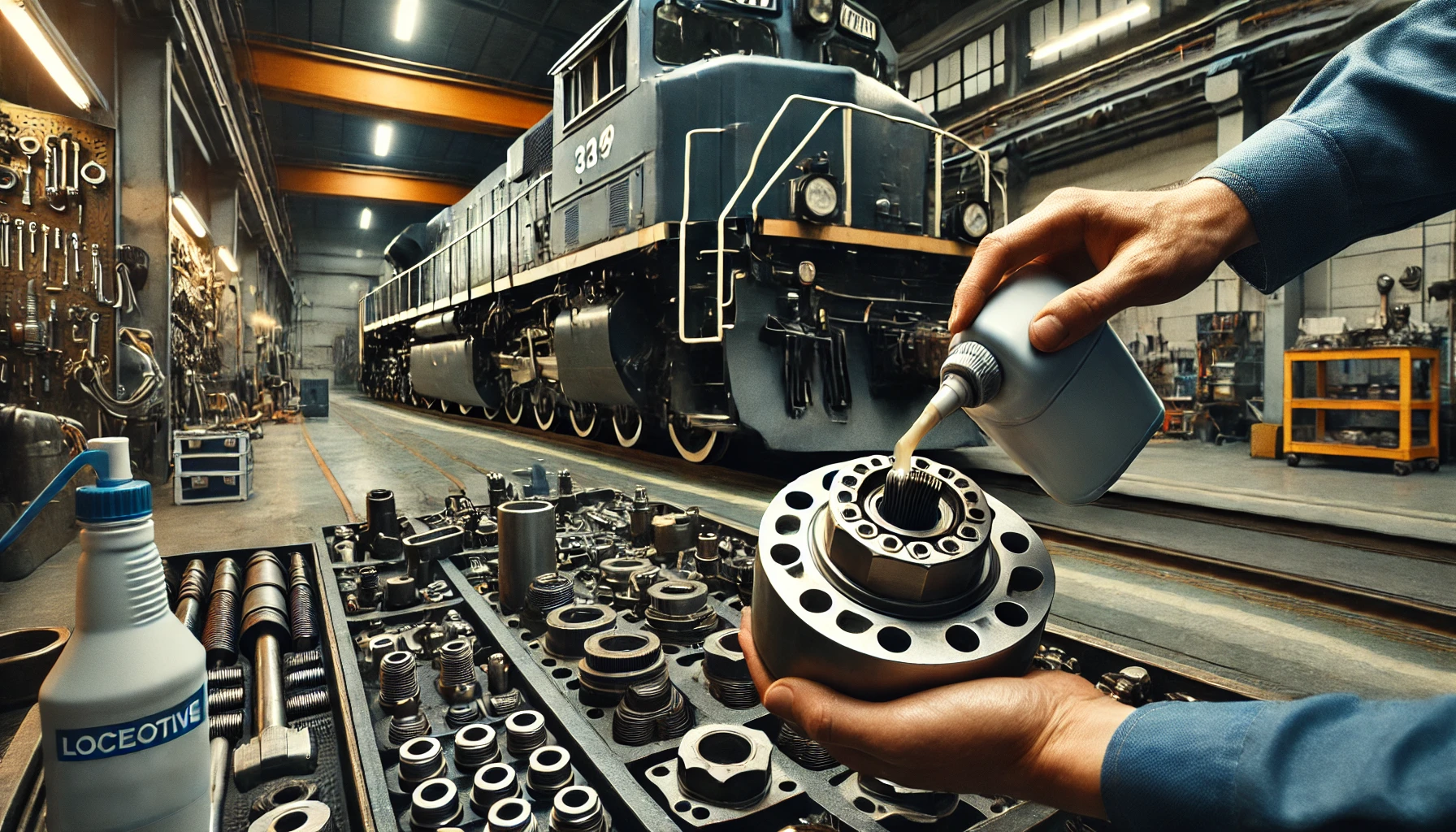

5. Train Maintenance Teams to Handle Parts Correctly

A common reason for premature spare part failure is improper handling and installation. If a crankshaft bearing is installed misaligned or a piston ring is fitted incorrectly, engine efficiency drops significantly, and failure occurs much sooner than expected.

🔹 Recommended Practice:

✅ Provide regular training sessions for maintenance personnel.

✅ Use precision tools during installation to ensure proper alignment and torque settings.

✅ Follow manufacturer installation guidelines to maximize performance and lifespan.

Unotech Engineering supports railway operators by providing expert guidance on the correct installation and maintenance of locomotive spare parts.

6. Monitor Performance and Analyze Failure Trends

The best way to predict future failures is to analyze past failures. Failure trend analysis allows railway operators to detect recurring issues in specific components, helping them make data-driven decisions on maintenance and replacements.

🔹 Recommended Practice:

✅ Use digital maintenance logs to track part replacements, failures, and repairs.

✅ Identify frequently failing components and upgrade to higher-grade replacements where necessary.

✅ Integrate IoT-based condition monitoring systems for real-time alerts.

Unotech Engineering supplies data-backed maintenance solutions, offering railway companies spare parts that outperform traditional components in durability and efficiency.

Conclusion: Small Changes, Big Savings

The key to extending the lifespan of locomotive spare parts lies in precision, planning, and prevention. By implementing preventive maintenance, using high-quality spare parts, ensuring proper lubrication, and training maintenance teams, railway operators can dramatically reduce operational costs and downtime.

As the rail industry continues to evolve, the demand for high-performance, long-lasting spare parts will only increase.

That’s why Unotech Engineering remains a trusted partner—delivering precision-engineered components that keep locomotives running at peak performance worldwide.